Synflex® Solstice™ air-brake tubing, made from proprietary thermoplastics, helps alleviate the supply chain volatility of traditional nylon raw materials used in the manufacture of traditional air-brake tubing. This highly engineered thermoplastic monowall tubing meets the performance of SAE J844, J1131, J2494-3, D.O.T. FMVSS 106 and OEM customer requirements for use on truck and trailer air-brake and auxiliary air-systems.

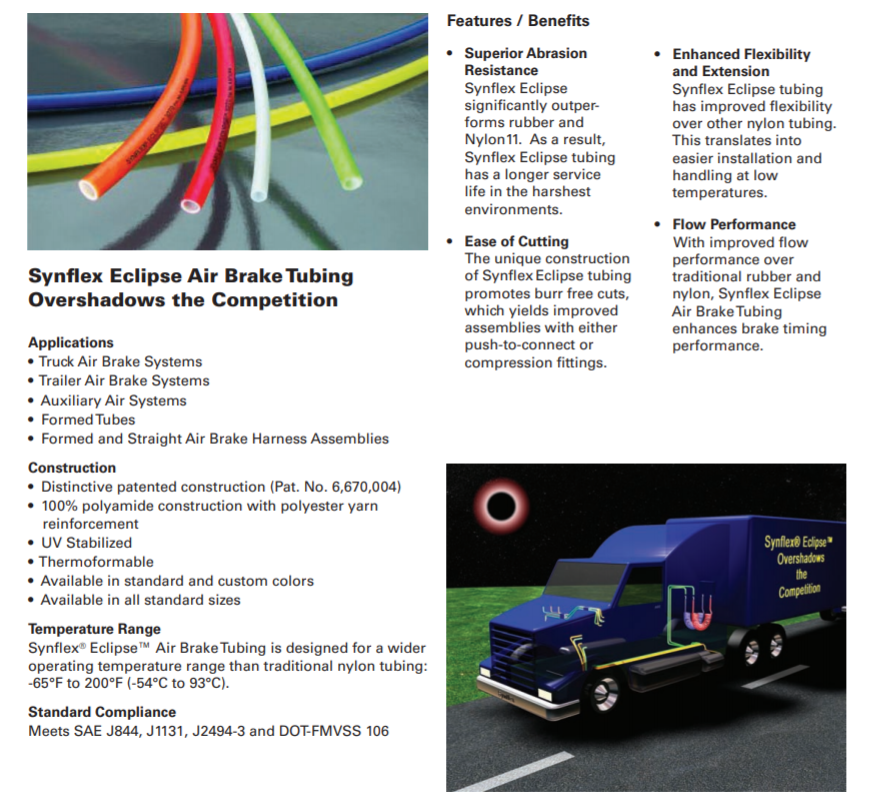

Its partner, the Synflex Eclipse, has superior abrasion resistance and significantly outperforms rubber and nylon11. This results in a longer service life in even the harshest of environments.

Easy to cut, Eclipse, multi-layered air-brake tubing promotes burr free cuts, which leads to improved assemblies with either push-to-connect or compression fittings. Has improved flexibility over other nylon tubing. This means easier installation and handling at low temperatures. Improved flow performance over traditional rubber and nylon, Eclipse air-brake tubing enhances timing performance.

Solstice and Eclipse tubing meet all of the performance criteria established in the trucking industry. Because they are made from entirely different raw materials, Solstice and Eclipse tubing are not expected to be subject to the supply chain disruptions of nylon that has created challenges for customers previously.

Solstice and Eclipse tubing haves an operating temperature range of -40° C to 93° C (-40° F to 200° F), are UV stabilized, thermoformable and available in both standard and custom colors. Solstice and Eclipse tubing can be supplied as formed tube, formed and straight air-brake harness assemblies and on reels in lengths up to 304.8 meters (1,000 feet).

The accompanying 1800 brass D.O.T. connectors are easy to use, fast to assemble, come in one-piece fittings and reusable field serviceable. Meets D.O.T. FMVSS 571.106 and SAE J1131 air-brake system performance requirements.